Ameritool 750 Series Fixed Force 26.3in, 80Lb, SS Gas Spring – 750-10-80-D2D2

AMERITOOL MANUFACTURING ATM-750-10-80-D2D2-P

26.3IN 80LB SS GAS SPRING

Description

750 Series Gas Springs

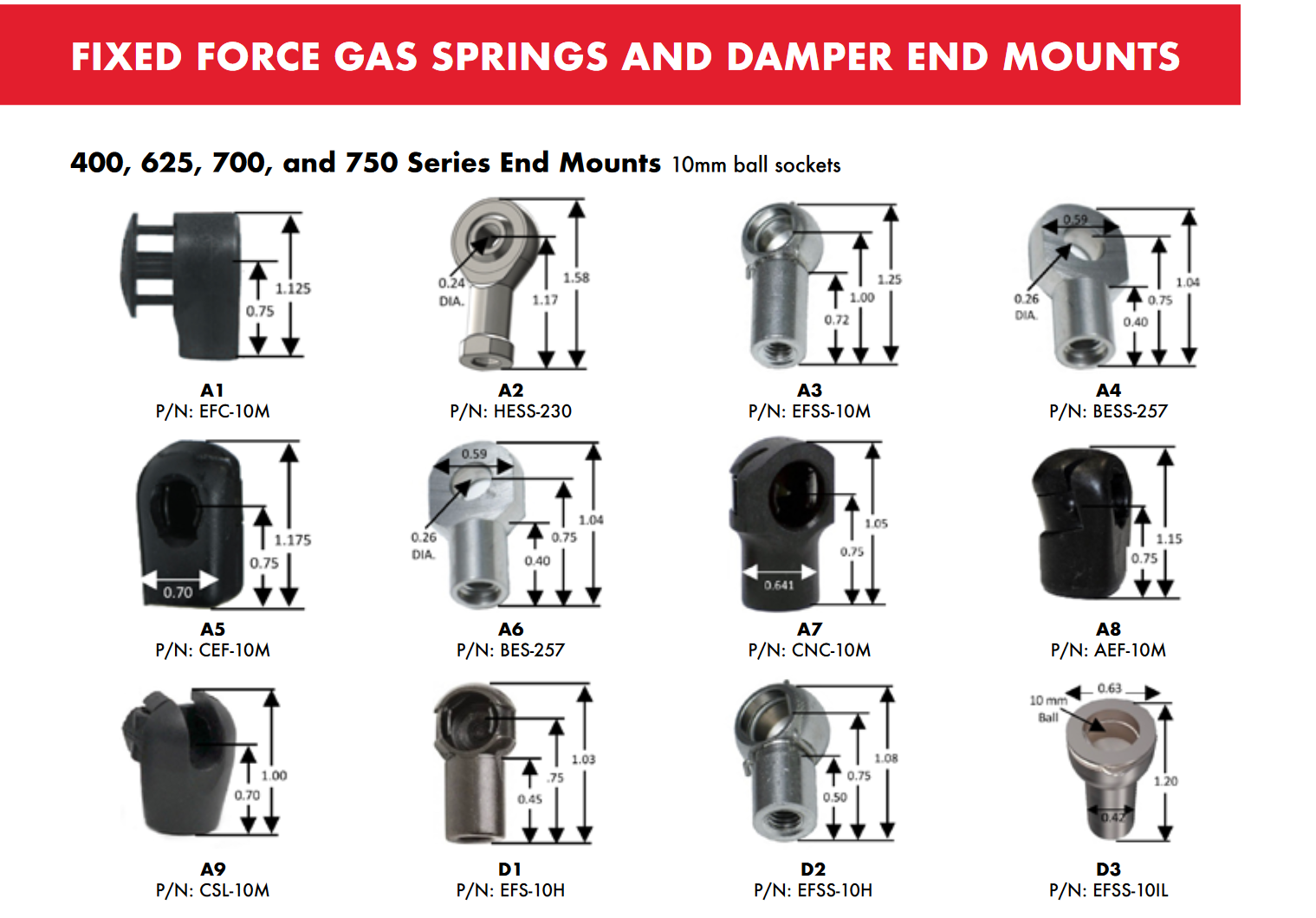

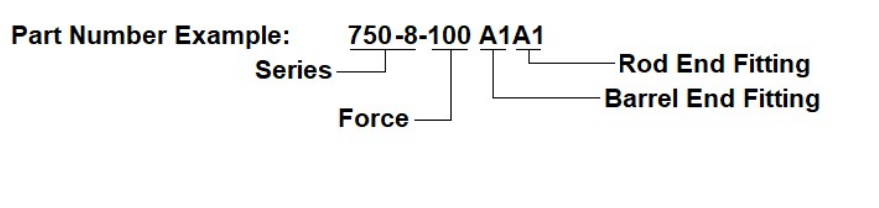

*Please verify rod and barrel end fittings before ordering.

High quality American Made 316 stainless steel fixed force gas springs are self-contained pneumatic devices capable of producing very large forces. Each gas spring is pressurized with nitrogen gas and contains a small amount of lubricating oil within the cylinder.

Used in opening or closing apparatus either by a vertical or horizontal travel for lifting, counterbalancing and motion control of doors, hatches, safety lids, hoods, cargo doors and access panels. Ameritool gas springs are suitable for all purposes and have unlimited application possibilities.

Features:

-

Reliable: Proven life of 125,0000 cycles

-

Durable: Unique rod seal & wiper design

-

Quality: Carbon Steel

-

Low Maintenance

Specifications:

-

Rod Diameter: .312”

-

Body Diameter: .750”

-

Stroke: 11.2”

-

Compressed Length: 15”

-

Extended Length: 26.3”

-

Lifting Force: 80lbs

-

Rod/ Barrel End Fittings: D2D2/ EFSS-10H

Notes:

-

Do not cycle more than 15 times per minute. Fast operation rates lead to excessive heat build-up resulting in internal seal damage.

-

Gas springs are under pressure. Please dispose of properly. Do not puncture or open.

-

Gas springs, tension springs, and dampers are not safety parts.

-

Do not extend or retract gas springs beyond their design specifications. Gas springs are not to be used as a dead stop.

FAQ

What is a gas spring?

Ameritool gas springs are self-contained, pneumatic devices capable of producing very large forces (5-1,200 lbs.) from a compacted piece. A gas spring consists of a piston attached to a shaft moving within a sealed cylinder charged with nitrogen. The piston has an orifice which allows gas pressure to pass through and act equally on both sides. It is the pressure acting on the shaft cross-sectional area which provides the springs its force.

How does a gas spring work?

A gas spring consists of a piston attached to a shaft moving within a sealed cylinder charged with nitrogen. The output forces are the result of the differential between the pressure in the cylinder and the atmospheric pressure outside the cylinder acting on the cross section of the piston/shaft. As the piston/shaft is compressed into the cylinder the internal pressure increases according to the volume of gas displaced by the rod.

What is the preferred mounting orientation of a gas spring?

In general, gas springs should be installed with the rod facing down to ensure the seals are lubricated and to reduce the permeation of nitrogen through the seal.

What is the expected life of a gas spring?

All gas springs lose output force over time. The rate at which force loss occurs varies greatly by application. Factors which affect the rate of loss include size of the gas spring, orientation, number of cycles, ambient temperature, vibration, and the geometry of the application. Considering all the variables, it is very difficult to estimate life expectancy accurately without actual testing of the application. Gas springs manufactured at Ameritool have surpassed 125,000 strokes in a test lab environment.

Additional information

| Weight | 0.0000 lbs |

|---|---|

| Dimensions | 0.0000 × 0.0000 in |

Brand

AMERITOOL

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.